Sudden Stoppage

Continuous Door Opening And Closing

Failure To Reach The Correct Floor

Doors Not Opening

Unusual Noises Or Sudden Drops

System Failures

Clogged Air Filters

Leaks Or Blockages In The Ducts

Power Or Compressor Malfunctions

Heat Exchanger Problems

Temperature Controller Faults

Electrical Leakage

Tripping

Short Circuits

High-Pressure Pump Fails To Start

Pump Operates But Fails To Supply Water

Pump Does Not Shut Off

Continuous Wastewater Flow

Inability To Produce Pure Water

Devices Are Upgraded To Identify And Detect Their Own Issues Autonomously.

Bcs Integrates With Other Devices For Cross-Monitoring, Enabling Early Error Detection And Warnings.

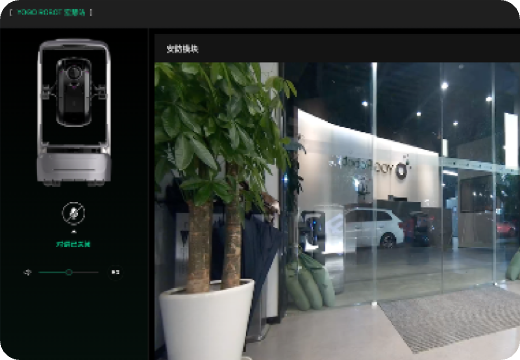

Robots Perform Additional Inspections To Identify Problems That May Not Be Immediately Apparent, Supplementing The System'S Overall Detection Capabilities.

The Bcs System, Integrated With Aiot Modules, Enables Proactive And Predictive Elevator Maintenance...

The Bcs System, Integrated With Aiot Modules, Enables Proactive And Predictive Elevator Maintenance...

The Bcs System, Equipped With Cell Modules, Enables Proactive And Predictive Maintenance For Air...

The Bcs System, Equipped With Cell Modules, Enables Proactive And Predictive Maintenance For Air...

Previously, Building Asset Inventory Required Manual Inspection And Data Collection, A Time-Consuming ...

Previously, Building Asset Inventory Required Manual Inspection And Data Collection, A Time-Consuming ...