-

Elevator Provider

CompaniesInnovation + Service ExpansionWith a saturated-developed market, market’s focus is shifting from simple new installations to enhancing after-sales services, retrofitting, and integrating eco-friendly, digital, and smart technologies.

-

Government & The PublicSafety regulation + oversight

Elevator Safety Is Paramount, Necessitating Robust Regulatory Frameworks. There'S A Need For Better Third-Party Monitoring Solutions Due To The Limitations In Current Government Oversight Capabilities.

-

Elevator Service

CompaniesStandardization + data sharingThe market's closed nature and the lack of uniform standards present challenges. There's a call for more openness from manufacturers regarding data sharing to reduce the cost and complexity of third-party integrations.

Competencies

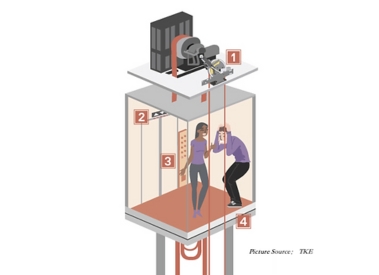

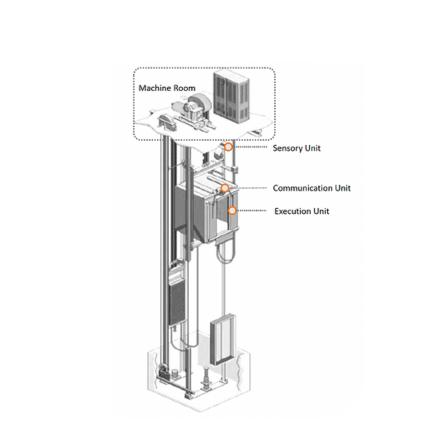

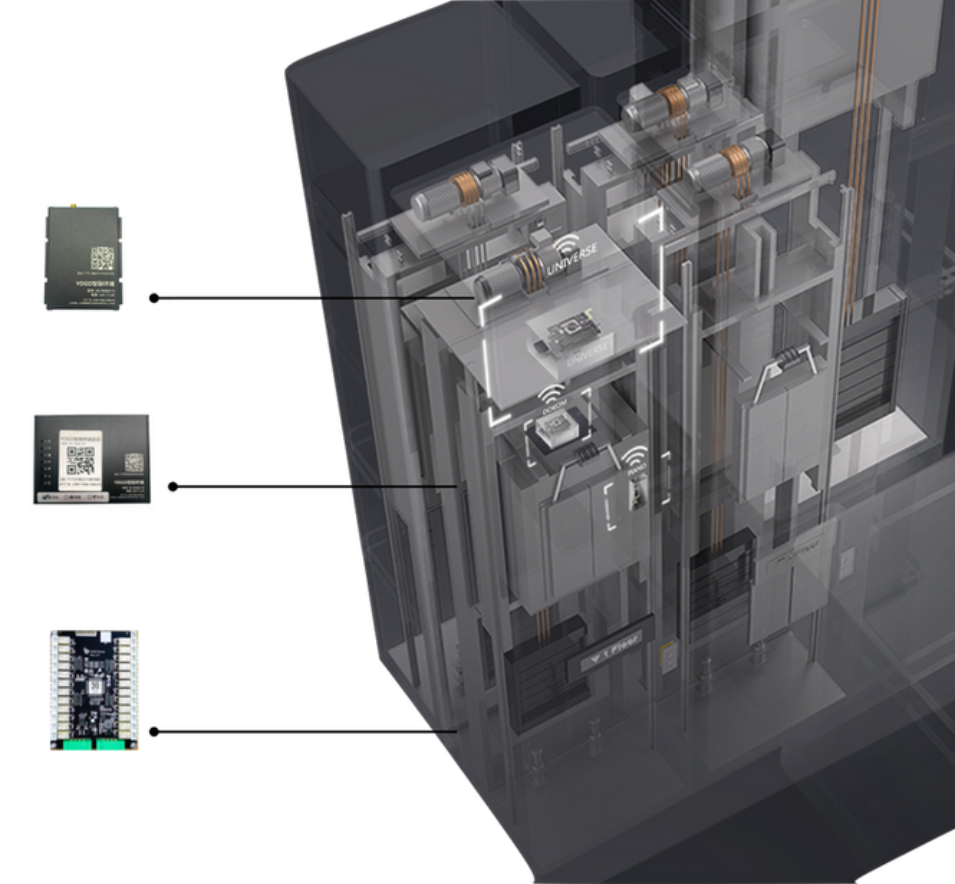

Dry contact wiring methods without altering or damaging its original wiring

In the industry, other peers who offer dry contact wiring methods typically perform secondary modifications to the original elevator wiring during the installation process, such as the wiring of floor buttons.

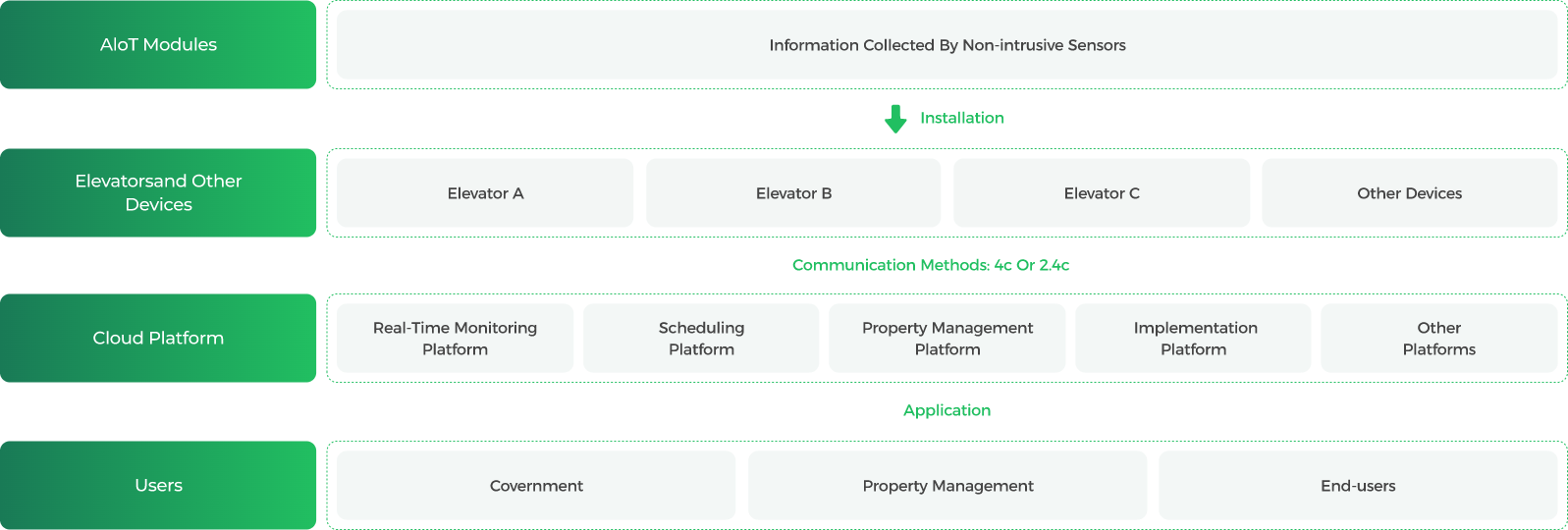

YOGO AIoT technology allows the addition of external sensors to elevator systems without altering or damaging their original wiring. These sensors operate independently, ensuring they do not interfere with the normal operation or performance of the elevators.

Dual Connection Assurance:

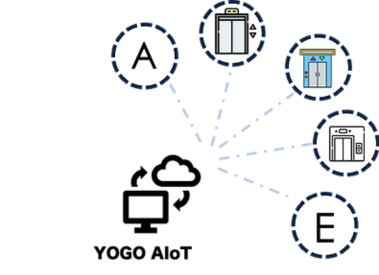

YOGO's system incorporates two communication channels: 4G and 2.4G. This dual-channel approach ensures stable and uninterrupted communication, significantly enhancing the quality and reliability of the technology.

High Communication Efficiency with Self-designed Ad-Hoc Network:

YOGO's proprietary Ad-Hoc Network Technology allows devices within the network to communicate directly with each other. This method increases the efficiency of communication, especially in environments where traditional network infrastructure may be lacking or overloaded.

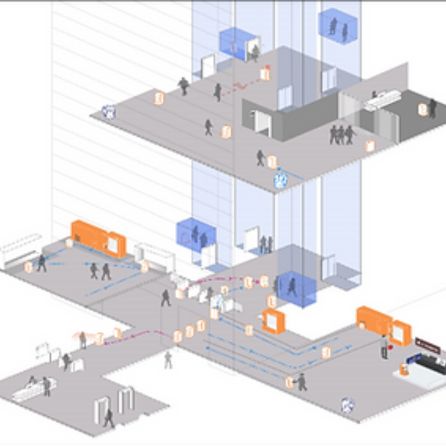

YOGO’s solution supports extensive operation among Multiple elevators, robots and gates, better than other IoT companies' Single-Robot, Single-Elevator Standard.

The system supports maximum collaboration of

-

30

Devices For

Localscheduling

-

4000

Devices For Global

Scheduling

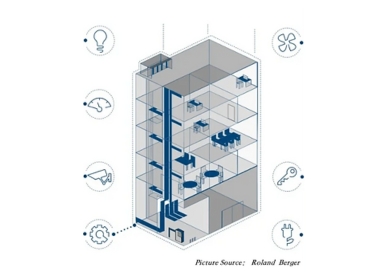

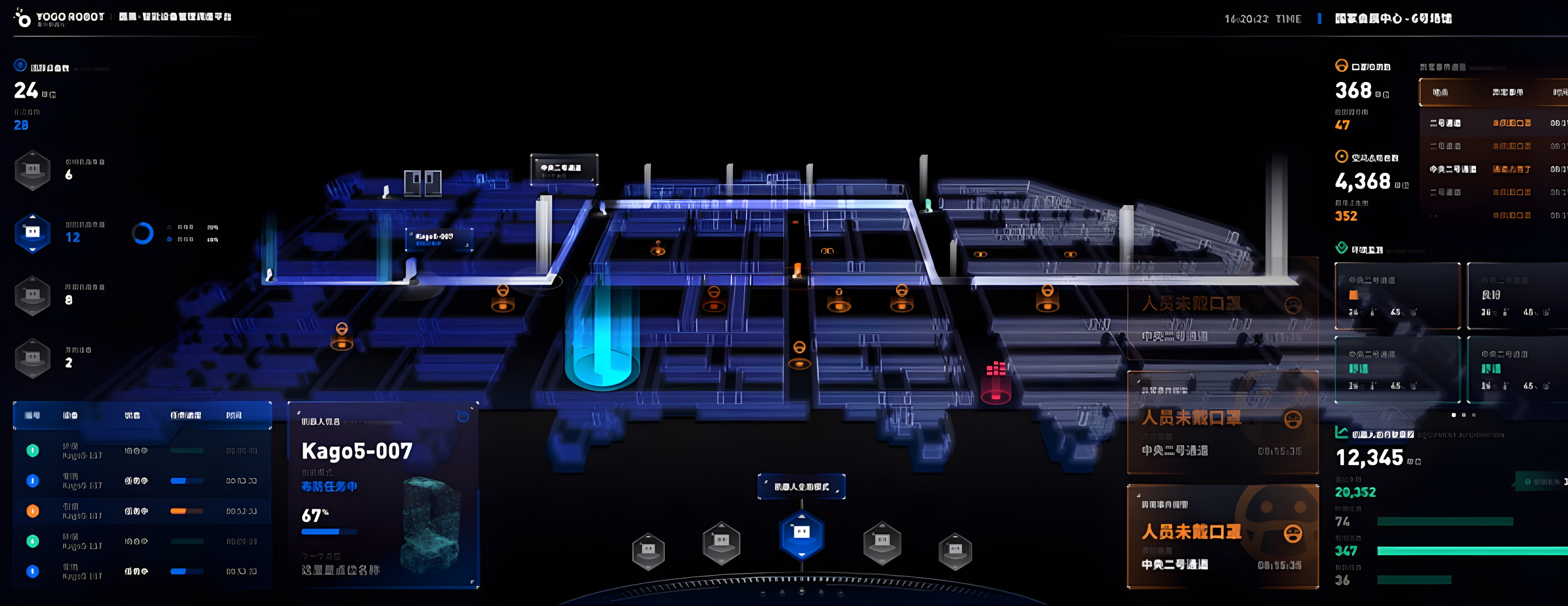

Enables The Live Tracking Of Elevator Operations; Issues Timely Warnings In Case Of Irregularities, Ensuring Emergency Response Mechanisms Are In Place.

-

Safety-Related InformationNcidents Such As Elevator Overrun, Squatting, Abnormal Acceleration Or Deceleration, Emergency Stops, Hovering, Door Openings During Operation, Inadequate Door Closures, Etc.

-

Information Related To The Aging Of Elevator OperationNcidents Such As Elevator Overrun, Squatting, Abnormal Acceleration Or Deceleration, Emergency Stops, Hovering, Door Openings During Operation, Inadequate Door Closures, Etc.

-

Information Regarding Usage BehaviorsNcidents Such As Elevator Overrun, Squatting, Abnormal Acceleration Or Deceleration, Emergency Stops, Hovering, Door Openings During Operation, Inadequate Door Closures, Etc.

Enables Complex Scheduling Among Multiple Robots, Multiple Elevators, Multiple Gates, Multiple Tasks And Etc., Achieving An Overall Efficiency And 24/7 Service.

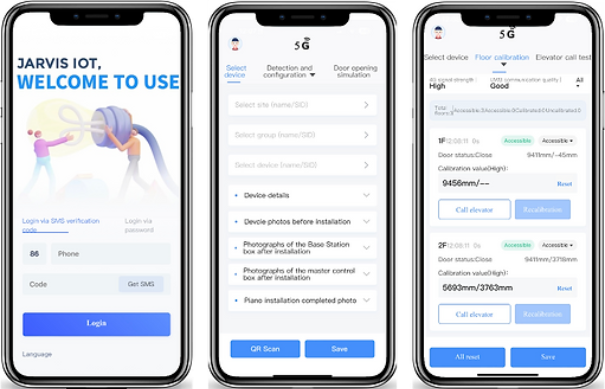

platform

YOGO Provides A Complete Suite Of Implementation Tools For The Installation, Commissioning, And Quality Assessment Of All Equipment. The Commissioning Tool Is Readily Available For Download And Use From Both The App Store And Google Play.

Once Equipped With YOGO'S Specialized Training And Guidance, Implementation Personnel Are Capable Of Seamlessly Utilizing These Tools. As A General Benchmark, The Installation Process For A Single Elevator In A 20-Floor Building Typically Takes No More Than 2 Hours To Complete.

Enables Complex Scheduling Among Multiple Robots, Multiple Elevators, Multiple Gates, Multiple Tasks And Etc., Achieving An Overall Efficiency And 24/7 Service.

-

Confirm Plans,IncludingModification Plans Forelevators,Gates,And Doors,And Robot Operation Plans

-

Coordinate With Elevatorequipment Maintenanceparties For On-Sitecooperation

-

Confirm & Sign

-

Building

Assessment -

Proposal

Confirmed -

Implementing

Lot And Robots -

Settlement

-

On-Going

Support

-

After On-Siteenvironmental Survey,Cerductrisk Assessmentand Implementationfeasibility Analysis

-

Offer Robotie Mobilityplanning And Relatedsolutions

-

Robot Scanning,Markinglot Device Installationand System Deployment

-

Function &Operation Tests

-

After-Sales Service.Operation Tracking.Malfunction Repair

-

68AIoT Patents

-

94 %Invention Patents

-

IS09001Quality Management System Certification

IS09001Quality Management System Certification -

IS027001Information Security Management System Certification

IS027001Information Security Management System Certification

|

Outer Packing |

L360'W200'126mm |

|

|

Gross Weigh |

4.089kg |

|

|

Operating Temperature |

-20-65ºC |

|

|

Operating Voltage |

AC 85-264V |

|

|

Maximum Working Current |

0.5A |

|

|

Maximum Working Power Consumption |

24W |

|

|

Signal Output |

24 Channels |

Dry Contact Signal Interface, 24/PCS, Maximum Support 3PCS |

|

Maximum Signal Input |

4 Channels |

Wet Contact, Used To Determine The Door Open And Close Signal Input Detection |

| Extended Communication Interface | UART |

For Debugging |

| RS485 |

Communicate With The Relay Board And Also Support Extemal Expanslon |

|

| Flash Onboard | 8m |

Save Parameters Whon Powor Otf |

| Way Of Communication | 2.4G | A proprietary protocol developed based on the 2.4-2.5Ghz frequency band, used for internal near-field communication between YOGO devices, including robots, Internet of Things, stations, etc. |

| Transmission power: 100mW | ||

| 4G | Supported network standards include GSM/GPRS/EDGE/CDMA1x/EVDO/WCDMA/TD-SCDMA/TDD/FDD | |

| UWB | A proprietary protocol developed based on the UWB frequency band for communication between Base Station and Master Control. | |

| Frequency range: 3.75GHz-4.25GHz | ||